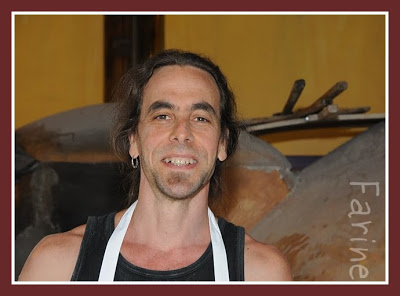

Roger Bouchard

)

), a building had to be either found or built. Bent on preserving the county’s heritage, Frank opted for the second solution. Heritage Charlevoix purchased an abandoned farm building in nearby Sainte-Irénée, had it sliced in half, and carried to the site on trucks.